1.9inch Segment e-Paper Module Manual

| ||

| ||

Overview

Parameters

| Dimensions | 1.9inch |

| Driver board dimensions | 51mm × 34 mm |

| Display dimensions | 41.35mm × 28.11 mm |

| Outline dimensions (screen only) | 49.35mm × 32.11mm × 1.13 mm |

| Operating voltage | 3.3V / 5V (5V is requuired for power and signal) |

| Communication bus | I2C |

| Segment | 91 segments |

| Display color | Black, White |

| Grey scale | 2 |

| Partial refresh time | 0.3s |

| Full Refresh time | 2s |

| Refresh power | < 5 mW(typ.) |

| Standby current | < 0.01uA (almost 0) |

- Refresh time: The refresh time is the experimental results, the actual refresh time will have errors, and the actual effect shall prevail. There will be a flickering effect during the global refresh process, this is a normal phenomenon.

- Power consumption: The power consumption data is the experimental results. The actual power consumption will have a certain error due to the existence of the driver board and the actual use situation. The actual effect shall prevail.

- IIC address: 0x3c and 0x3d are used by default

Instruction transfer address: 0x3c/0x3e Data transfer address: 0x3d/0x3f

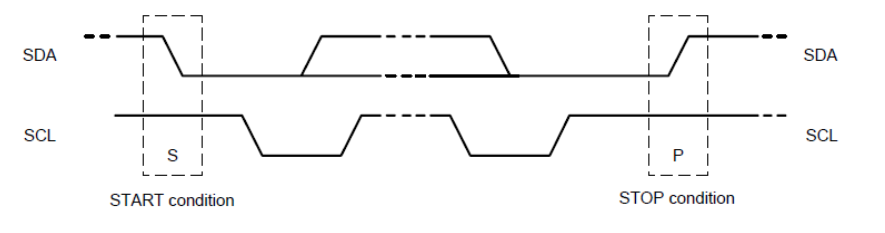

I2C Communication Protocol

From the above function pin table, it is known that I2C communication is used, I2C communication, one data cable, and one clock cable. There are three types of signals in the process of transmitting data on the I2C bus: start signal, end signal, and response signal.

Start signal: When SCL is high level, SDA jumps from high level to low level, and starts to transmit data.

End signal: When SCL is at high level, SDA transitions from low level to high level, ending data transmission.

Response signal: After receiving 8-bit data, the IC that receives data sends a specific low-level pulse to the IC that sends data, indicating that the data has been received.

- I2C writing data sequence

First, the host (that is, the Raspberry Pi, collectively referred to as the host) will send a start signal, and then combine its I2C 7-bit address and the write operation bit into 8-bit data and send it to the slave (that is, the TSL2581 sensor module, collectively referred to as the following) Slave), the slave will respond with a response signal after receiving it, the master will send the address of the command register to the slave at this time, the slave will receive the send response signal, at this time the master will send the value registered in the command, and the slave will respond with a response signal until the host sends a stop signal, the I2C write data operation ends.

- I2C reading data sequence

First, the host will send a start signal, and then combine its I2C 7-bit address and write operation bits into 8-bit data and send it to the slave. After receiving it, the slave will respond with a response signal, and the host will send the address of the command register To the slave, the slave receives the send response signal, at this time the master sends a start signal again, and combines its 7-bit address and read operation bits into 8-bit data to send to the slave, and the slave sends a response after receiving the signal, and then send the value in its register to the host, and the host will give a response signal until the host sends a stop signal, and the communication ends.

- 1.9inch Segment e-Paper I2C address

Command Address: 0x3c

Data Address: 0x3D

Working Principle

This product is an e-Paper device adopting the image display technology of Microencapsulated Electrophoretic Display, MED. The basic principle is that the charged nanoparticles suspended in the liquid are subjected to the electric field to produce migration. The e-Paper screen display patterns by reflecting the ambient light, so it has no background light requirement. Under ambient light, the e-Paper screen still has high visibility with a wide viewing angle of almost 180 degrees. It is the ideal choice for e-reading.

Program Principle

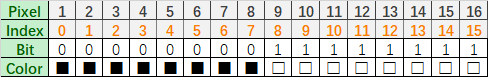

We define the pixels in a monochrome picture, 0 is black and 1 is white.

White:□: Bit 1

Black:■: Bit 0

- The dot in the figure is called a pixel. As we know, 1 and 0 are used to define the color, therefore we can use one bit to define the color of one pixel, and 1 byte = 8pixels

- For example, If we set the first 8 pixels to black and the last 8 pixels to white, we show it by codes, they will be 16 bit as below:

For computer, the data is saved in MSB format:

So we can use two bytes for 16 pixels.

Segment Code Table

Number correspondence table (without decimal point):

0: 0 x bf, 0 x 1f

1: 0 x 1f (position 1), 0 x 00, 0 x 1f (other positions)

2: 0 x fd, 0 x 17

3: 0 x f5, 0 x 1f

4: 0 x 47, 0 x 1f

5: 0 x f7, 0 x 1d

6: 0 x ff, 0 x 1d

7: 0 x 21, 0 x 1f

8: 0 x ff, 0 x 1f

9: 0 x f7, 0 x 1f

The decimal point and % are the 5th place in the 4th, 8th, and 10th positions respectively.

The 13th position can display Celsius (0 x 05) and Fahrenheit (0 x 06), the 0th position is the bottom line, the 1st position is the middle line, the 2nd position is other displays, the 3rd position shows the Bluetooth logo, and the 4th position Bit shows the power identification, number 14 is useless.

Precautions

1. For the screen that supports partial refresh, please note that you cannot keep refreshing the screen partially when using it, you need to perform a full refresh on the screen after refreshing partially. Otherwise, the screen display effect will be abnormal and cannot be repaired!

2. Note that the screen cannot be powered on for a long time. When the screen is not refreshed, set the screen to sleep mode or power off. Otherwise, if the screen maintains a high voltage state for a long time, the screen will be damaged and cannot be repaired!

3. When using the ink screen, it is recommended that the refresh interval be at least 180s, and refresh at least every 24 hours. If the ink screen is not used for a long time, the ink screen should be clear and stored. (Refer to the datasheet for specific storage environment requirements.)

4. After the screen enters sleep mode, the image data sent will be ignored, and it can only be refreshed normally after re-initialization.

5. The working voltage requirement of the ink screen is 3.3V. If you buy a bare screen, if you need to match the 5V working environment when designing the circuit, it is recommended to do some level conversion processing. The new version (V2.1 and subsequent versions) has added a level processing circuit, which can support both 3.3V and 5V working environments. The old version can only support 3.3V working environments. You can confirm the version before using it. (The ones with 20-pin chips on the PCB are generally new versions.)

6. The FPC cable of the screen is relatively fragile, pay attention to bending the cable along the horizontal direction of the screen when using it, and not bending the cable along the vertical direction of the screen.

7. The screen of the ink screen is relatively fragile, so pay attention to avoid dropping, bumping, and pressing hard.

8. We recommend that customers use the sample program we provide and use the corresponding development board to test after getting the screen.

Raspberry Pi

Provides BCM2835, WiringPi, IO, RPI (Python) libraries and demos.

Hardwware Connection

If the e-Paper you have is the HAT version which has 40pin GPIO, you can directly attach the e-Paper HAT on Raspberry Pi, otherwise, you can connect your e-Paper to Raspberry Pi by an 8pins cable provided.

To connect the e-Paper, you can follow the table below:

| e-Paper | Raspberry Pi | |

| BCM2835 | Board | |

| VCC | 3.3V | 3.3V |

| GND | GND | GND |

| SDA | SDA.1 | 3 |

| SCL | SCL.1 | 5 |

| RST | 4 | 7 |

| BUSY | 17 | 11 |

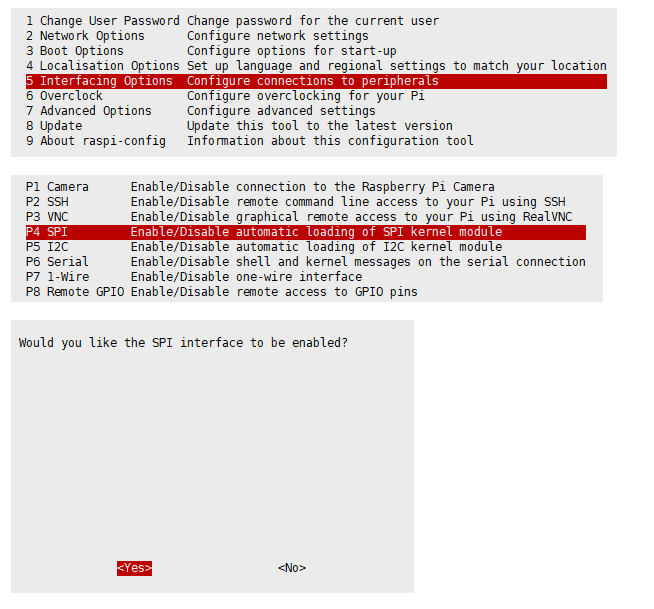

Enable I2C Interface

- The communication interface of e-Paper is SPI, to use it, we should firstly enable the SPI interface.

- Open terminal of Raspberry Pi, and open the configuration by the following command:

sudo raspi-config

- Choose Interfacing Options -> SPI -> Yes

- Restart Raspberry Pi

sudo reboot

Install libraries

Open the terminal of Raspberry Pi and run the following commands to install the corresponding libraries:

- Install lg library:

#Open the Raspberry Pi terminal and run the following command: wget https://github.com/joan2937/lg/archive/master.zip unzip master.zip cd lg-master make sudo make install #For more details, you can find in the source code:https://github.com/gpiozero/lg

- Install BCM2835 libraries

#Open the Raspberry Pi terminal and run the following command wget http://www.airspayce.com/mikem/bcm2835/bcm2835-1.71.tar.gz tar zxvf bcm2835-1.71.tar.gz cd bcm2835-1.71/ sudo ./configure && sudo make && sudo make check && sudo make install # For more information, please refer to the official website: http://www.airspayce.com/mikem/bcm2835/

- Install WiringPi libraries

#Open the Raspberry Pi terminal and run the following command sudo apt-get install wiringpi #For Raspberry Pi systems after May 2019 (earlier than before, you may not need to execute), you may need to upgrade: wget https://project-downloads.drogon.net/wiringpi-latest.deb sudo dpkg -i wiringpi-latest.deb gpio -v # Run gpio -v and version 2.52 will appear. If it does not appear, the installation is wrong #Bullseye branch system use the following command: git clone https://github.com/WiringPi/WiringPi cd WiringPi ./build gpio -v # Run gpio -v and version 2.60 will appear. If it does not appear, it means that there is an installation error

- Download demo (you can skip this step if you have downloaded it.)

sudo apt-get install p7zip-full wget https://files.waveshare.com/upload/f/f6/E-Paper-Segment-Code.zip 7z x E-Paper-Segment-Code.zip -O./e-Paper cd e-Paper/RaspberryPi/

- Compile demo (Note: -j4 is compiled with 4 threads, the number can be modified by yourself)

# Now at e-Paper/RaspberryPi location cd c sudo make clean sudo make -j4

- Run the demo

sudo ./main

Run Python Demo

- Install library

sudo apt-get update sudo apt-get install python3-pip sudo apt-get install python3-pil sudo apt-get install python3-numpy sudo apt-get install python3-smbus

- Install function library

sudo apt-get update sudo apt-get install python-pip sudo apt-get install python-pil sudo apt-get install python-numpy sudo pip install RPi.GPIO sudo apt-get install python-smbus

- Download demo (you can skip this step if you have downloaded it.)

sudo apt-get install p7zip-full wget https://files.waveshare.com/upload/f/f6/E-Paper-Segment-Code.zip 7z x E-Paper-Segment-Code.zip -O./e-Paper cd e-Paper/RaspberryPi/

- Run the demo

#Make sure it is in e-Paper/RaspberryPi/ cd python/examples/ sudo python3 main.py

STM32

The program provided is based on STM32F103RBT6, so you should connect it according to the pins of STM32F103RBT6. If you want to port the program, you must connect it based on the actual pins.

Hardware Connection

| e-Paper | STM32 |

| VCC | 3.3V |

| GND | GND |

| SDA | PB9/D14 |

| SCL | PB8/D15 |

| RST | PA9/D8 |

| BUSY | PA8/D7 |

Take our XNUCLEO-F103RB as an example, the connection is as follows:

Run the Demo

- Download the demo and unzip it to enter the E-Paper_code to view the following content:

- Find the STM32 program file directory after decompression, open epd-segmented-demo.uvprojx in the E-Paper-Segment-Code\STM32\epd-segmented-demo\MDK-ARM directory, and you can see the program.

- Comment out the corresponding function in main.c:

// EPD_1in9_test();

Modify it to:

EPD_1in9_test();

- Then, compile it to download.

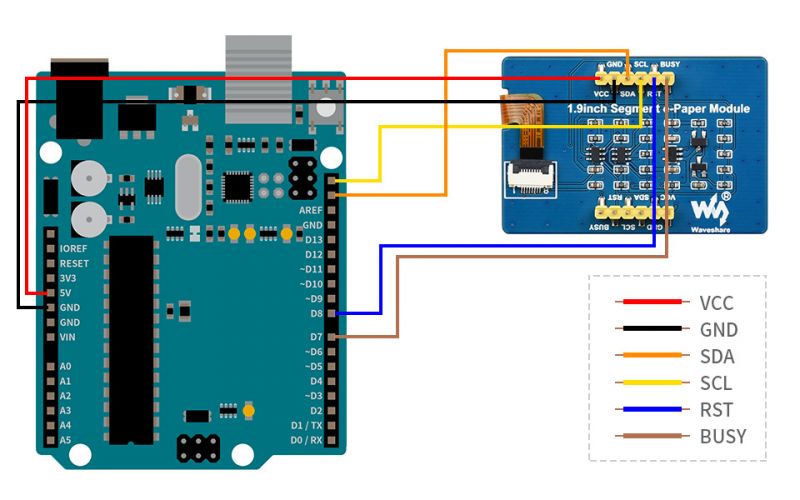

Arduino

All demos have been tested in Arduino uno. If you use Arduino in different models, you need to check the connection of the pins.

Hardware Connection

| e-Paper | Arduino UNO | Mega2560 |

| Vcc | 5V | 5V |

| GND | GND | GND |

| SDA | SDA | SDA |

| SCL | SCL | SCL |

| RST | D8 | D8 |

| BUSY | D7 | D7 |

Install Compile Software (Windows)

Run the Program

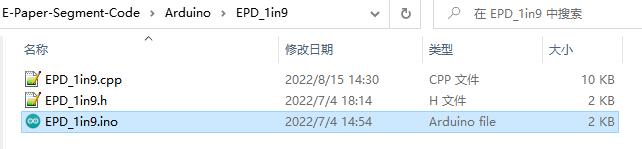

Please download E-paper-segment-code and unzip it. Arduino program is in "~/Arduino/…"

Open the test program: E-Paper-Segment-Code\Arduino\EPD_1in9\EPD_1in9.ino

After selecting the board in Arduino IDE, compile and download it.

Resource

Documentation

- Schematic

- 1.9inch Segment e-Paper Datasheet

- 1.9inch Segment e-Paper V1.1 Datasheet(current version)

- IST7134 Driver Manual

Program

Related Resources

FAQ

Question about Software

{{{5}}}

{{{5}}}

{{{5}}}

{{{5}}}

1. First check whether the wiring is correct.

2. Check whether the spi is turned on and whether the parameters are configured correctly (spi baud rate, spi mode and other parameters).

{{{5}}}

Question about Hardware

{{{5}}}

Device selection can use the model in the schematic diagram we provide or choose according to the data sheet.

{{{5}}}

{{{5}}}

Confirm whether the BUSY pin is normally initialized to input mode.

It may be that there is no normal reset, try to shorten the duration of the low level during reset (because the power-off switch is added to the drive circuit, the reset low level is too long, which will cause the drive board to power off and cause the reset to fail).

If the busy function sends the 0x71 command, you can try to comment it out.

{{{5}}}

Question about Screen

- 【Storage conditions】: Temperature range: below 30°C; Humidity range: below 55%RH; Maximum storage time: 6 months.

- 【Transportation conditions】: Temperature range: -25~70°C; Maximum transportation time: 10 days.

- 【After unpacking】: Temperature range: 20°C±5°C; Humidity range: 50±5%RH; Maximum storage time: Assemble within 72 hours.

{{{5}}}

- Full brush: The electronic ink screen will flicker several times during the refresh process (the number of flickers depends on the refresh time), and the flicker is to remove the afterimage to achieve the best display effect.

- Bureau brush: The electronic ink screen has no flickering effect during the refresh process. Users who use the partial brushing function note that after refreshing several times, a full brush operation should be performed to remove the residual image, otherwise the residual image problem will become more and more serious, or even damage the screen (currently only some black and white e-ink screens support partial brushing, please refer to product page description).

- refresh rate

- During use, it is recommended that customers set the refresh interval of the e-ink screen to at least 180 seconds (except products that support the local brush function).

- During the standby process (that is, after the refresh operation), it is recommended that the customer set the e-ink screen to sleep mode, or power off operation (the power supply part of the ink screen can be disconnected with an analog switch) to reduce power consumption and prolong the life of the e-ink screen. (If some e-ink screens are powered on for a long time, the screen will be damaged beyond repair.)

- During the use of the three-color e-ink screen, it is recommended that customers update the display screen at least once every 24 hours (if the screen remains the same screen for a long time, the screen burn will be difficult to repair).

- Full brush: The electronic ink screen will flicker several times during the refresh process (the number of flickers depends on the refresh time), and the flicker is to remove the afterimage to achieve the best display effect.

- Application

- The e-ink screen is recommended for indoor use. If it is used outdoors, it is necessary to avoid direct sunlight on the e-ink screen, and at the same time, take UV protection measures, because charged particles will dry out under strong light for a long time, resulting in loss of activity and failure to refresh. This situation is irreversible. When designing e-ink screen products, customers should pay attention to determining whether the use environment meets the requirements of e-ink screen.

- The e-ink screen is recommended for indoor use. If it is used outdoors, it is necessary to avoid direct sunlight on the e-ink screen, and at the same time, take UV protection measures, because charged particles will dry out under strong light for a long time, resulting in loss of activity and failure to refresh. This situation is irreversible. When designing e-ink screen products, customers should pay attention to determining whether the use environment meets the requirements of e-ink screen.

{{{5}}}

{{{5}}}

{{{5}}}

{{{5}}}

Different batches of e-paper diaphragms and electrophoretic matrices require different voltage values when driving the display due to materials, manufacturing processes, etc. The waveform of the e-ink screen is reflected in the relationship between grayscale, voltage and temperature. Generally speaking, after each batch of electrophoresis matrix is generated, there will be a corresponding waveform file in the form of a .wbf file. The film manufacturer will provide the waveform file and electrophoresis matrix to the manufacturer of the electronic paper screen, and then the The manufacturer of electronic paper screen integrates the protection board, substrate and driver and then provides it to customers; if the waveform file does not correspond to the screen, it is likely that the display cannot be displayed or the display effect is unsatisfactory. Generally, the waveform file has OTP built into the driver IC of the ink screen when leaving the factory, and some programs we provide also call external waveform files to drive the e-ink screen.

{{{5}}}

Others

{{{5}}}

{{{5}}}

{{{5}}}

{{{5}}}

{{{5}}}

Support

Technical Support

If you need technical support or have any feedback/review, please click the Submit Now button to submit a ticket, Our support team will check and reply to you within 1 to 2 working days. Please be patient as we make every effort to help you to resolve the issue.

Working Time: 9 AM - 6 PM GMT+8 (Monday to Friday)