Details

Large Torque | Metal Case | Dual-Axis Constant Force | 360° Magnetic Encoder

| Torque | 35KG.CM |

|---|---|

| Rotation angle | 360° (0~4096) |

| Position sensor resolution | 0.088° (360°/4096) |

| Mechanism limit angle | No limit |

| Operating voltage | 9 ~ 12.6 V (typ. 12V) |

| Gear | high precision steel gear (reduction ratio 1:345) |

| No-load speed | 0.222sec/60° (45RPM) |

| Encoder type | 12Bits magnetic encoder |

| ID range | 0 ~ 253 |

| Baudrate | 38400bps ~ 1Mbps (1Mbps by default) |

| No-load current | 150mA |

| Locked-rotor current | 2.8A |

| Kt | 12.5KG.CM/A |

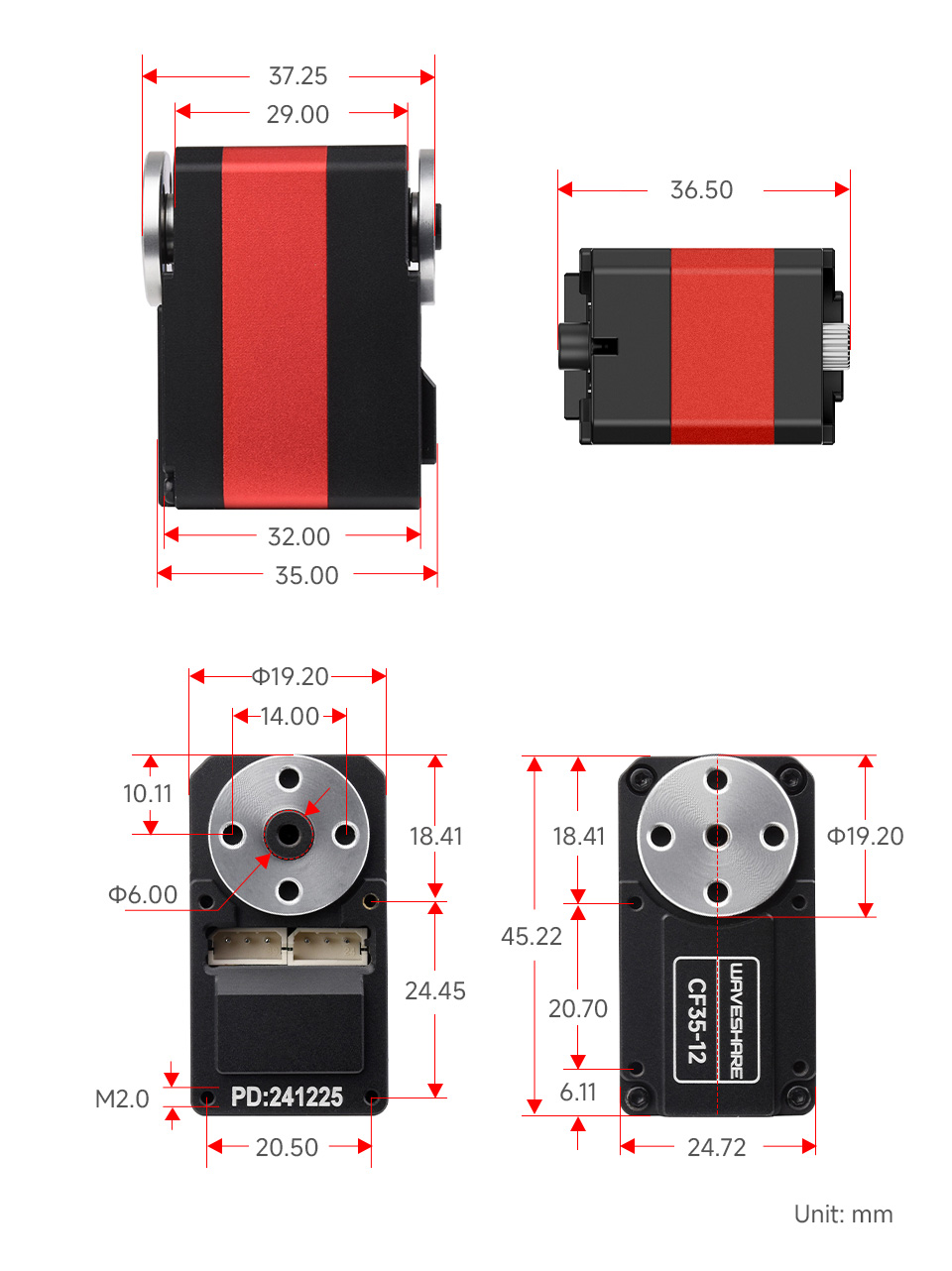

| weight | 70.5±1g |

| Feedback | Position, Load, Speed, Input Voltage, Current, Temperature |

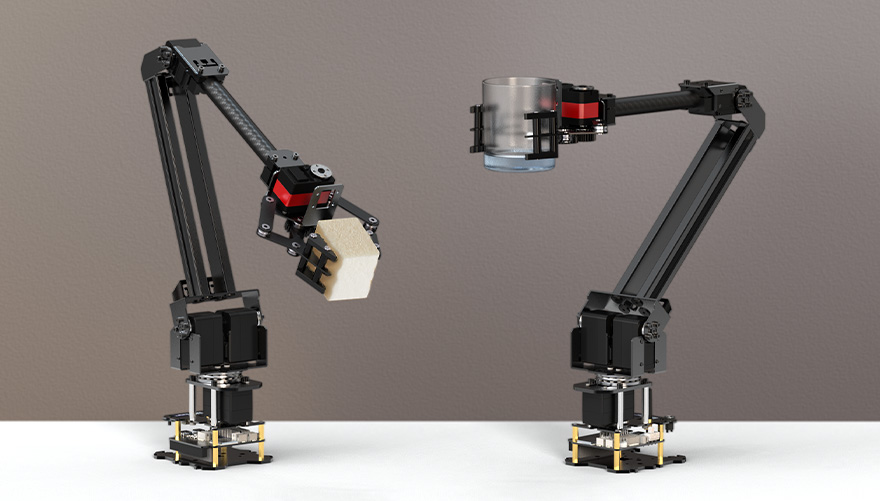

Adopts an innovative direct-drive servo design with force-position control, the servo can maintain a preset torque value to grip objects. Whether the object is hard or fragile, it ensures precise grasping without damaging the object's surface.

* for reference only, please refer to the Package Content for the detailed part list.

To improve the heat tolerance, size stability, rigidity, and mechanical performance of the case

Up to 35KG.CM torque on 12V operating voltage, suitable for building multi-axial compact steering robotic projects such as quadruped, hexapod, and robotic arm, etc.

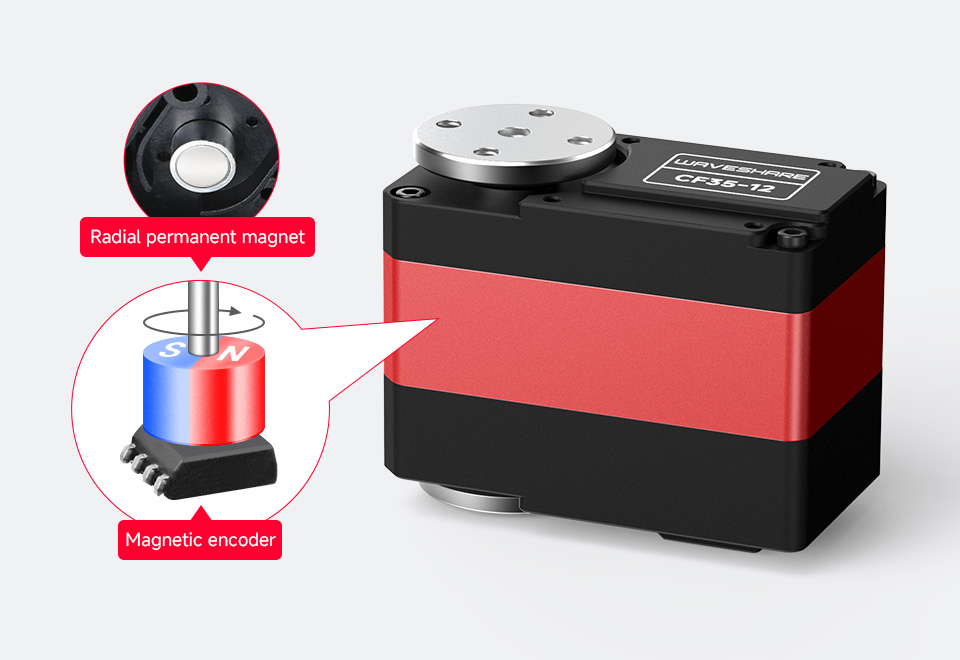

Adopts 12-bit high-precision magnetic encoding angle sensor. Compared with the carbon film potentiometer, the angle of the magnetic encoder is enlarged to 360°, and the resolution is increased by 4 times. Since there is a gap and no friction between the magnetic encoder and the radial magnet, the servo lifetime is effectively extended.

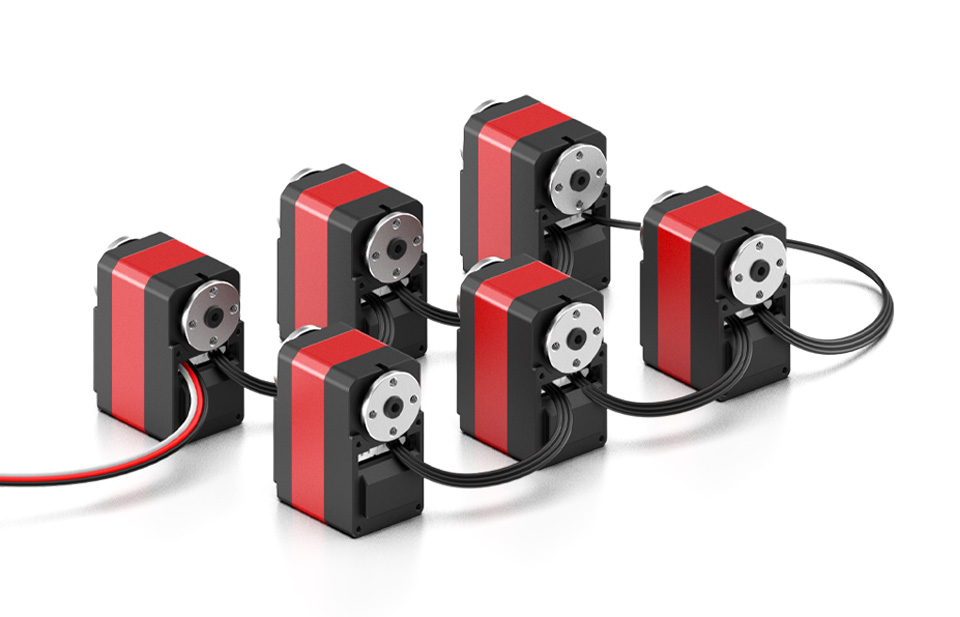

Up to 253 servos controlling at the same time, with simple wiring, reducing the occupation of the serial port

Note: though one channel UART can control up to 253 servos, due to the high power of the servos, it is necessary to consider whether the power supply solution is enough when using too many servos.

The speed and acceleration values are settable to make the motion effect softer and reduce impact from inertia

360° installation at any position, one button to set the current position as middle position. Easy to install and debug

Click Release to unlock, then turn the servo to the middle position where you want to set

Click Set Middle Position then confirm.

Turn the servo to any angle, then click Middle, and the servo will automatically return to the middle position initially set.

The servo Will Provide Various Feedback Like Position, Load, Speed, Input Voltage, Current and Temperature In Real Time, and will unload force protection when the servo is overheated or overloaded

suitable for more application scenarios

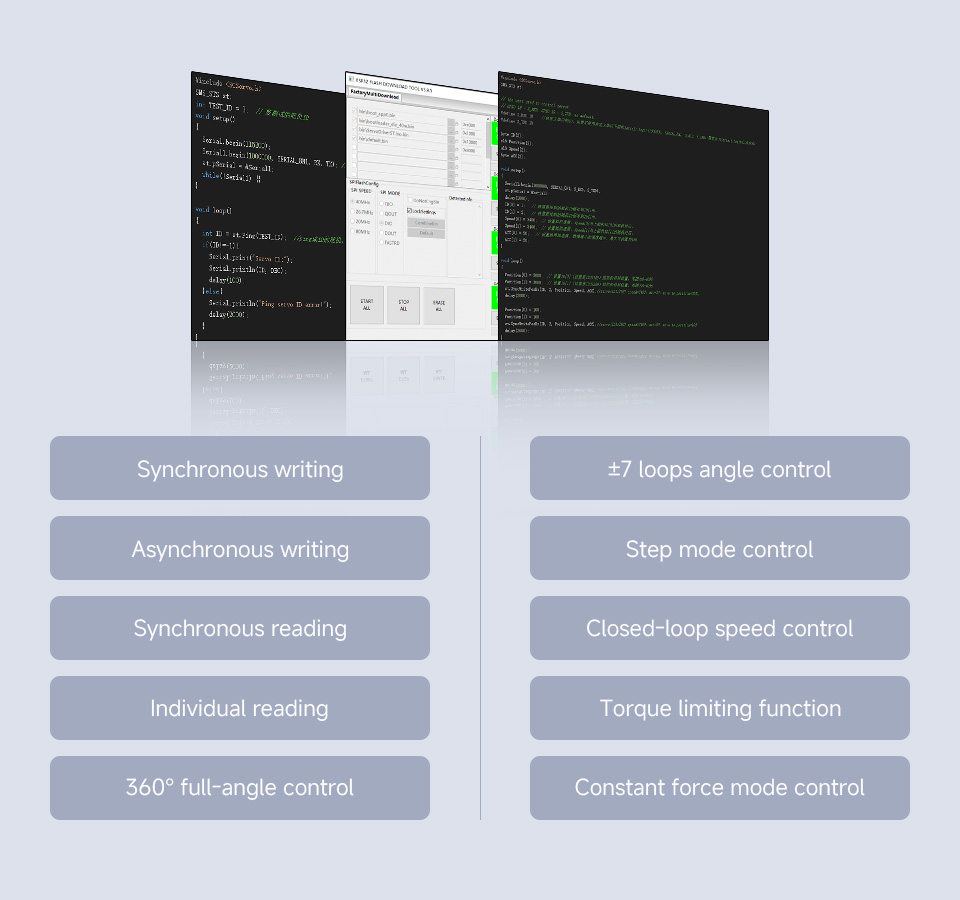

Angle servo mode

Default mode, the angle position is controllable at 0~360°

Speed closed-loop mode

Intelligently control and maintain speed when the load changes

Step mode

Can perform step motion relative to the current position

Supports angle position control in both positive and negative directions up to 7 loops under the default precision setting, but the number of loops will not be saved in case of power loss. Lowering the angle resolution can double the number of control loops

High strength aluminum servo wheels

Using T6061 aluminum alloy, good corrosion-resistance

Metal bearing shaft

Lower working noise, better stability and mechanical performance

All-metal bracket

More convenient to combine it with other devices

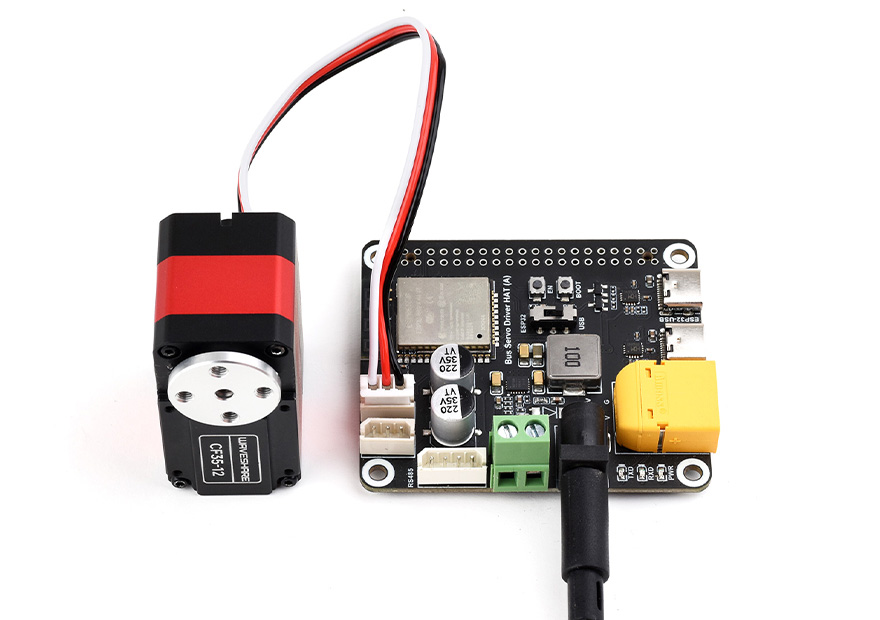

connecting with Bus Servo Driver HAT (A) drive board, we provide open-source control demo of the servo

* for reference only, the drive board is NOT included.

* Resources for different product may vary, please check the wiki page to confirm the actually provided resources.

| Product | Voltage | Control Method | Precision | NO-LOAD SPEED | Continuous Rotation | LOCKED-ROTOR TORQUE * | LOCKED-ROTOR CURRENT | Range | Feedback |

|---|---|---|---|---|---|---|---|---|---|

| WP90 | 4.8 ~ 7.4 | PWM | ≤2° | 0.1sec/60° | - | 2.3kg.cm | 1.0A | 180° | - |

| SC09 | 4.8 ~ 8.4 | TTL | 300°/1024 | 0.1sec/60° | √ | 2.3kg.cm | 1.0A | 300° | √ |

| SC15 | 4.8 ~ 8.4 | TTL | 180° / 1024 | 0.16 sec / 60° | √ | 15kg.cm | 1.5A | 180° | √ |

| ST3020 | 6 ~ 14.0 | TTL | 360° / 4096 | 0.167sec / 60° | √ | 25kg.cm | 2.7A | 360° | √ |

| ST3215 | 6 ~ 12.6 | TTL | 360° / 4096 | 0.222 sec / 60° | √ | 30kg.cm | 2.7A | 360° | √ |

| ST3025 | 6 ~ 12.6 | TTL | 360° / 4096 | 0.117sec / 60° | √ | 40kg.cm | 4.4A | 360° | √ |

| ST3235 | 6 ~ 12.6 | TTL | 360° / 4096 | 0.222sec/60° | √ | 30kg.cm | 2.7A | 360° | √ |

| CF35-12 | 9.0 ~ 12.6 | TTL | 360° / 4096 | 0.222sec/60° | √ | 35kg.cm | 2.8A | 360° | √ |

| RSBL35-24-HS | 9.0 ~ 24.0 | RS485 | 360° / 4096 | 0.087sec/60° | √ | 35kg.cm | 1.8A | 360° | √ |

| RSBL45-24 | 9.0 ~ 24.0 | RS485 | 360° / 4096 | 0.142sec/60° | √ | 45kg.cm | 2.3A | 360° | √ |

| RSBL85-12 | 9.0 ~ 12.0 | RS485 | 360° / 4096 | 0.167sec/60° | √ | 85kg.cm | 7.9A | 360° | √ |

| RSBL85-24 | 9.0 ~ 24.0 | RS485 | 360° / 4096 | 0.154sec/60° | √ | 85kg.cm | 5.6A | 360° | √ |

| RSBL120-24 | 9.0 ~ 24.0 | RS485 | 360° / 4096 | 0.2sec/60° | √ | 120kg.cm | 4A | 360° | √ |

* the Locked-rotor torque is measured at the typical voltage of each servo, please refer to the documentation in the wiki for more details

Weight: 0.153 kg

Quick Overview

CF35-12 x1